Beaver® Standard Modular CSDs

Beaver® in short

Beaver® CSDs are reliable, fuel efficient, have low maintenance costs and are extremely productive at all dredging depths. We have a proven track record of 60 years, with almost 1,000 of these cutter suction dredgers supplied worldwide since 1963.

Over the years, the design of our Beaver® is continuously improved using the latest technological developments and feedback from our customers. Innovations and digital solutions are added - such as electrification and operations monitoring solutions - which improves operational efficiency and a sustainable performance.

These dredgers are capable of dredging compacted soil types and materials, such as clay and rock. High accuracy and a continuous rate of production ensure that our Beaver® vessels are ideal for many dredging jobs, such as land reclamation and the construction of new harbour basins and canals.

Why choose a Beaver® dredger?

- reliability due to high maximum uptime and high performance

- lifetime product support with unique dredging expertise at any moment of production

- short delivery time, available from stock

- opportunity of customer financing

- best value for money, lowest cost per m3.

Find the right Beaver® for your project

To help you select the right Beaver® for your project, a first selection can be made based on the pumping capacity of the dredger. The output of the various Beaver® dredgers for medium fine sand (235μm 1,950kg/m3) is shown in the graph. This can be matched with the required output and distance to be pumped. The graphs are based on output expressed in cubic meters of in-situ solids per effective pump hour and elevation at the end of the pipeline of 4 metres.

Output based on free-flowing material

The calculated output curves only indicate the pumping capacity, based on free-flowing material. In practice soil properties may vary from free-flowing to hard-to-excavate material. The nature of the material to be dredged and the project conditions should be taken into account when using the curves to estimate actual outputs.

FAQ

What is the price of a Beaver®?

The price will vary due to local regulations, transport requirements and insurance, amongst other things. Please feel free to contact us for a more detailed price indication.

Do you supply spare parts?

We can supply you with all the spare parts you need for the systems installed on your vessel and take care of the necessary logistics. Through our global stocking locations, we can supply spare parts whenever you need them, allowing you to maintain your systems efficiently and economically.

An optional Beaver kit is available for all of our Beavers®. This kit contains all the critical spare parts you need for the initial stages of your operation.

What is the delivery time?

Royal IHC has stock at all times. Please contact us for the most up-to-date information on current stock levels.

Can Royal IHC help me with the financing of my dredging equipment?

Our experienced and knowledgeable financing team liaises with you and lenders to create a suitable financing structure, managing any potential risks. Financing institutions have separate funds to invest in sustainable ‘green’ solutions and financing is done against a lower interest rate than brown solutions. This in turn lowers the cost for asset owners.

What are your terms and conditions?

Our general terms and conditions are applicable. You can download these here.

The future is electric!

We are expanding our portfolio with electrical Beavers®.

A total solution for your challenges

We provide a complete portfolio of standard modular products and services, with which we fulfill the complete range of basic dredging client needs. We not only offer a Beaver® dredger; customised to our client’s needs we provide a unique, full solution, making a combination of suitable standard modular products and a wide range of services.

With option packages (e.g. depth extension), equipment (e.g. Boosters and floating pipelines) and work boats. All of this comes with an aftermarket service and possibility to train operators and provide consultancy on projects to support our clients to enhance their operational efficiency. Some of these services are included in the basic package, such as operations monitoring, training, certain spare parts and there is the option to work with a dredge master for a month.

Auxiliary equipment

Additional equipment options include:

Additional services

We offer services applicable for:

Operations Monitoring: Insight is the essence of efficiency

Understanding how an asset performs is vital in order to maximise operational efficiency and earning potential. Through the use of data driven intelligence we provide this insight and control for your Beaver® dredger. Operational data is presented in an easy-to-understand dashboard, available on both desktop and mobile.

All new built Beavers® come with three year access to our Operations Monitoring dashboard, consultancy support and first line support. With our hardware retrofit packages (one-time fee) it is also suitable for existing Beaver® dredgers that meet certain technical criteria. After the 3-year access period we can extend the support period by a further 3 years.

Innovation developments

Our Beaver® dredgers are equipped with state-of-the-art technology and already offer some key features:

- dismountable and transportable over land

- suitable for single-handed operations

- low emissions and environmentally-friendly operation

Current developments on the basic products focus on a sustainable performance and improved operational efficiency, including:

- electrification

- asset compliance for environmental legislation

- digital solutions, for example online operations support and spare parts ordering.

Available Beaver® types

The standardised series is available with a dredging depth ranging from 6-18 metres and a suction pipe diameter ranging from 300-650mm. Optional extras include increased dredging depths, anchor booms, spud carriage installations, swivel bends, and automation.

| Beaver® | Beaver 30 | Beaver 40 | Beaver 45 | Beaver 50 | Beaver B65 DDSP |

|---|---|---|---|---|---|

| Total power | 294 kW | 483 kW | 895 kW | 1350 kW | 2819 kW |

| Cutter power | 30 kW | 52 kW | 110 kW | 170 kW | 700 kW (max) |

| Dredging depth | 6 m | 8 m | 10 m | 14 m | 18 m |

| Pipe diameter | 310 mm | 390 mm | 450 mm | 500 mm | 650 mm |

| Matching work boat | DMC 1050 | DMC 1050 | DMC 1050 | DMC 1050/1450 | DMC 1450 |

Your project, our solution

Beavers® can be used for a wide range of dredging projects. They reclaim land from the sea, dredge entrance channels, and create or extend harbours by removing soil from land. They are also used to clean up pollution and silt from rivers, lakes and canals.

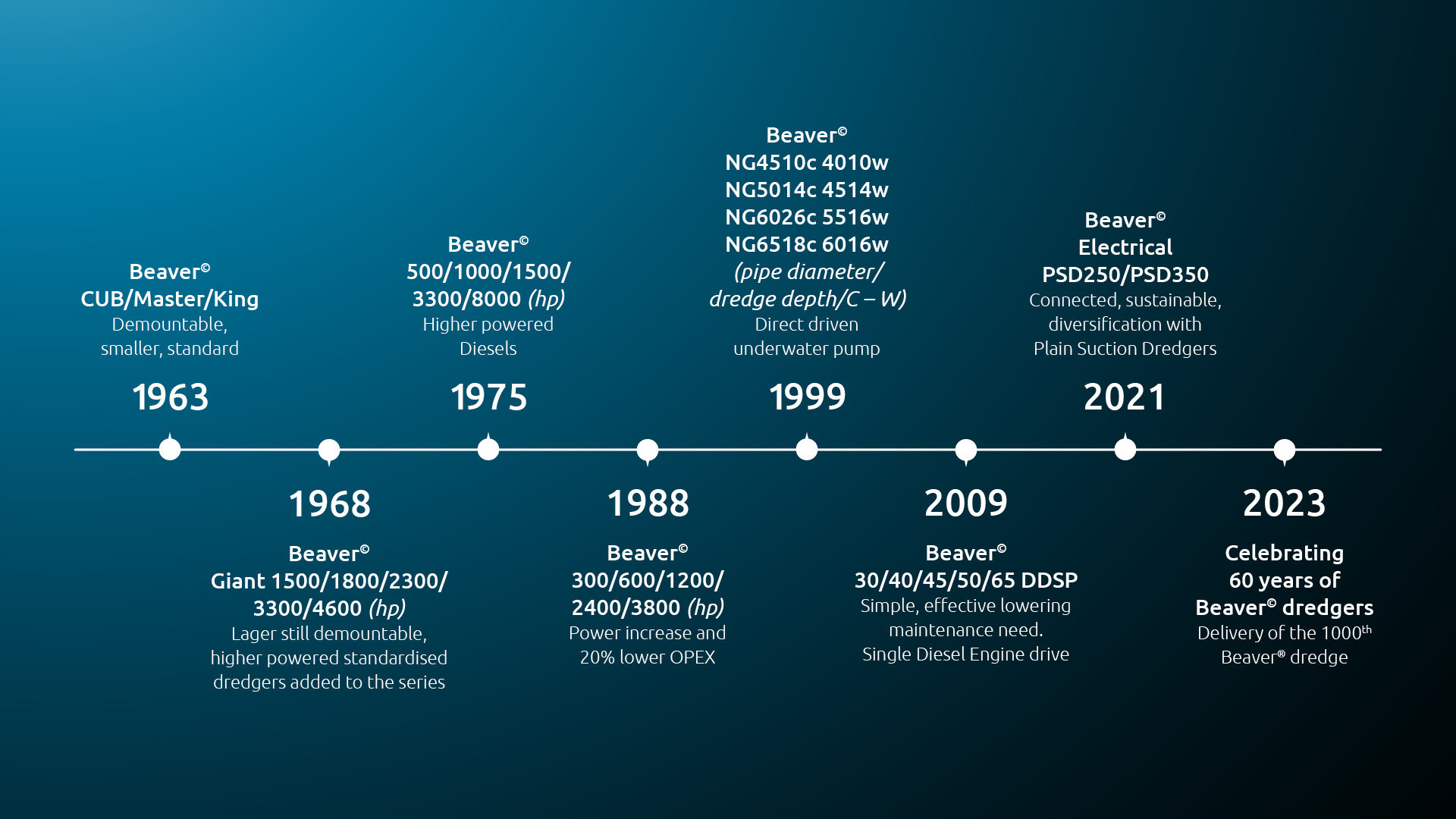

History

Since 1963, we have supplied almost 1000 Beaver® dredgers worldwide.

More information?

-

Corné

HoutProduct Manager

Interested in the total solutions that we can offer?

Fill in the form and our experts will guide you through our portfolio.